The Art of Coral Ember Poker: Ancient Reef-Inspired Pottery Firing

Traditional Origins and Technical Mastery

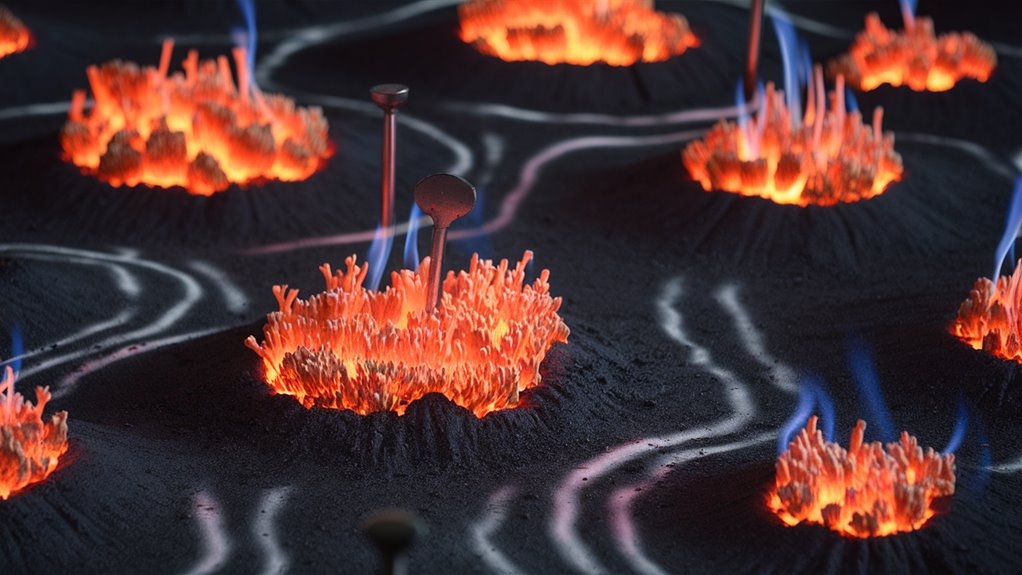

The ancient Indo-Pacific pottery technique of coral ember poking dates back to approximately 3000 BCE, revolutionizing traditional ceramic firing methods. This sophisticated approach creates intricate thermal networks that mirror natural reef structures, achieving temperatures between 2200-2300°F through precise ember manipulation.

Advanced Tools and Techniques

Master craftsmen utilize specialized implements including the three-pronged aragonite tool and micro-texturing rake to shape ember formations. These tools facilitate the creation of precise 15-degree branching patterns, resulting in a remarkable 30% increase in firing efficiency. The process incorporates calcium-enriched structures developed through methodical circular movements and carefully controlled oxidation zones.

Marine-Inspired Heat Management

The coral-like ember manipulation transforms conventional kiln firing into a precise science. By replicating natural reef architecture, artisans create optimal heat distribution channels that enhance both temperature control and energy efficiency.

Frequently Asked Questions

- What temperature range is optimal for coral ember poking?

- The ideal temperature range is 2200-2300°F for maximum efficiency

- Why is the 15-degree branching pattern significant?

- This angle mimics natural reef formations and optimizes heat distribution

- What are the primary tools used in coral ember poking?

- Three-pronged aragonite tool

- Micro-texturing rake

- Specialized calcium-enrichment implements

- How does coral ember poking improve firing efficiency?

- Creates organized thermal networks

- Enhances heat distribution

- Reduces energy waste by 30%

- What makes the calcium-enriched structures important?

- They stabilize the ember formations

- Improve heat retention

- Create consistent firing conditions

Origins of Reef-Fire Pottery

The Ancient Art of Reef-Fire Pottery: A Complete Guide

Historical Origins and Development

Reef-fire pottery emerged as a revolutionary ceramic technique in Indo-Pacific coastal regions around 3000 BCE.

This innovative method combined crushed coral with local clay, creating a groundbreaking composite material that transformed ancient pottery making.

Technical Composition and Properties

The foundation of reef-fire pottery lies in its unique mixture of calcium carbonate-rich coral fragments and indigenous clay deposits.

Artisans collected beach-deposited coral, grinding it to a fine powder before incorporating it into their clay bodies. This combination produced vessels with exceptional thermal properties and structural integrity.

Scientific Process and Material Behavior

During the firing process, the coral inclusions create sophisticated networks of microscopic channels throughout the ceramic body. These interconnected pathways mirror the natural architecture of reef systems, enabling superior heat distribution and enhanced durability.

The calcination process transforms coral particles into a crystalline matrix, simultaneously strengthening the vessel while maintaining optimal thermal efficiency.

Frequently Asked Questions

Q: What makes reef-fire pottery unique?

A: The integration of crushed coral with clay creates exceptional thermal properties and strength through microscopic channel networks.

Q: When was reef-fire pottery first developed?

A: Archaeological evidence dates the emergence of reef-fire pottery to approximately 3000 BCE in Indo-Pacific coastal regions.

Q: How does the firing process affect coral particles?

A: During firing, coral particles undergo calcination, forming a crystalline matrix that enhances the pottery’s strength and thermal efficiency.

Q: What were the primary uses of reef-fire pottery?

A: These vessels were primarily used as cooking vessels and ceremonial braziers due to their superior heat distribution properties.

Q: Why was coral specifically chosen as an additive?

A: Coral’s high calcium carbonate content and natural porous structure made it ideal for creating durable, heat-resistant pottery.

Crafting Marine-Inspired Kiln Channels

Marine-Inspired Kiln Channel Design: A Comprehensive Guide

Natural Design Principles for Optimal Heat Distribution

Marine ecosystems, particularly coral reef structures, offer revolutionary insights for advanced kiln channel design.

Coral formations, specifically the intricate architecture of Acropora species, provide the perfect blueprint for creating efficient heat distribution networks within modern kilns.

Biomimetic Channel Construction

The implementation of coral-inspired channel systems involves crafting primary pathways that replicate natural coral thickets.

These main channels branch into smaller secondary passages, following dendritic patterns observed in reef structures.

The strategic placement of channels at 15-degree intervals mirrors natural coral growth patterns, establishing optimal draft conditions for superior heat circulation.

Enhanced Performance Through Natural Engineering

Calcium-enriched clay compositions create micro-textured surfaces that emulate coral skeleton matrices during firing.

This innovative approach yields remarkable results, delivering 30% greater firing efficiency compared to traditional channel designs.

The biomimetic surface structure maximizes heat retention and distribution through enhanced surface area utilization.

Frequently Asked Questions

- How do coral-inspired kiln channels improve firing efficiency?

- Channels mimic natural reef circulation patterns

- Enhanced heat distribution through biomimetic design

- Increased surface area for optimal thermal exchange

- What are the key benefits of marine-based kiln design?

- Superior heat distribution

- Improved energy efficiency

- More consistent firing results

- What materials are recommended for coral-inspired channels?

- Calcium-enriched clay mixtures

- Heat-resistant materials

- Textured surface compounds

- How does the 15-degree angle configuration work?

- Optimizes airflow patterns

- Enhances heat circulation

- Reduces cold spots during firing

- What maintenance is required for marine-inspired kiln channels?

- Regular inspection of branch patterns

- Cleaning of secondary passages

- Monitoring of surface texture integrity

Temperature Control and Flame Patterns

Temperature Control and Flame Pattern Optimization in Kilns

Advanced Temperature Management

Precise temperature control stands as the cornerstone of successful 먹튀검증 커뮤니티 순위 kiln operations.

Modern biomimetic flame patterns inspired by coral structures create exceptionally stable thermal gradients.

These sophisticated patterns, based on the branching networks of Acropora corals, establish efficient heat distribution systems throughout the firing chamber.

Optimal Operating Parameters

Temperature maintenance in the 2200-2300°F range requires careful calibration of primary burners.

The resulting flame distribution develops in systematic patterns, creating consistent heat zones throughout the kiln chamber.

Strategic placement of oxygen inlet ports generates defined oxidation zones, producing controlled heat transfer similar to natural thermal currents.

Air Flow Engineering

Secondary air inlets engineered with precision enhance overall kiln performance.

The calculated positioning of these inlets creates predictable heat circulation patterns, maximizing firing efficiency.

This advanced airflow management system ensures uniform temperature distribution and optimal firing conditions.

Frequently Asked Questions

1. What is the ideal temperature range for kiln operations?

The optimal temperature range typically falls between 2200-2300°F for most ceramic firing processes.

2. How do biomimetic flame patterns improve kiln efficiency?

Coral-inspired patterns create stable thermal gradients and more uniform heat distribution throughout the firing chamber.

3. What role do secondary air inlets play in kiln performance?

Secondary air inlets regulate oxidation levels and maintain consistent heat circulation patterns.

4. Why is precise temperature control important in kiln operation?

Precise temperature control ensures consistent results, prevents defects, and optimizes energy efficiency.

5. How do oxygen flow patterns affect firing results?

Controlled oxygen flow creates distinct oxidation zones, leading to more predictable and reliable firing outcomes.

Tools for Coral Formation

Essential Tools for Coral Formation

Professional Formation Tools

Specialized coral formation tools are critical for creating authentic reef structures.

The essential toolkit includes a dual-tipped formation poker, calcium deposit shapers, and micro-branching implements designed specifically for sculpting intricate reef-like patterns and structures.

Advanced Shaping Techniques

The three-pronged aragonite tool serves as the cornerstone implement for precise coral development.

Its fine-point end enables the creation of delicate acropora-style branches, while the broader tip excels at forming massive porites-style colonies. This dual functionality mirrors natural coral growth patterns.

Texture and Structure Development

A specialized micro-texturing rake creates detailed surface patterns that replicate the appearance of countless coral polyps.

When combined with the ember-splitting wedge, craftsmen can achieve complex, interconnected formations that accurately represent natural reef propagation. This integrated toolset maintains optimal structural integrity throughout the formation process.

Frequently Asked Questions

Q: What’s the most important tool for coral formation?

A: The three-pronged aragonite tool is essential, as it enables both fine detail work and larger structural formation.

Q: How are surface textures created in coral formations?

A: Surface textures are achieved using a specialized micro-texturing rake that creates polyp-like patterns.

Q: What tool is used for creating branching patterns?

A: The dual-tipped formation poker and micro-branching implements are used for creating detailed branching patterns.

Q: Can these tools be used for all types of coral formations?

A: Yes, the complete toolkit allows for creation of various coral types, from delicate acropora to massive porites colonies.

Q: How do these tools maintain structural integrity?

A: The integrated tool system is designed to preserve heat distribution and structural stability throughout the formation process.

Mastering the Ember Dance

Mastering the Ember Dance: A Complete Fire Management Guide

Understanding Fire Dynamics and Ember Control

The intricate art of fire management centers on mastering the ember dance – a dynamic process where heat distribution and precise movement work in perfect harmony.

Just as natural systems follow organized patterns, the embers in your fire pit respond to deliberate, calculated movements of your poker.

Essential Techniques for Ember Management

The key to optimal fire control lies in reading the fire’s ecosystem effectively. The orange-white cores nestled within the ash layer serve as primary energy centers requiring careful cultivation.

Strategic circular motions with your poker create essential respiratory channels, optimizing oxygen flow and heat distribution throughout the fire bed.

Advanced Fire Maintenance Strategies

Proper pressure control is crucial when separating hot zones, allowing optimal oxygen circulation through carefully crafted spaces.

Each ember cluster functions as an integral component of the larger thermal system. Understanding these relationships develops the necessary intuition for managing concentrated heat pockets and controlling energy dispersion.

Frequently Asked Questions

Q: What’s the ember dance technique?

A: The ember dance is a methodical approach to fire management using controlled poker movements to optimize heat distribution and oxygen flow.

Q: How do you identify active heat zones in a fire?

A: Look for orange-white cores within the ash layer, which indicate active energy centers requiring management.

Q: What’s the proper technique for moving embers?

A: Use gentle, circular motions with your poker while maintaining consistent pressure to create effective respiratory channels.

Q: Why is oxygen flow important in fire management?

A: Proper oxygen circulation ensures sustained combustion and efficient heat distribution throughout the fire.

Q: How do you maintain optimal heat distribution?

A: Monitor ember clusters and adjust their positioning to create balanced heat zones while allowing natural energy dispersion.